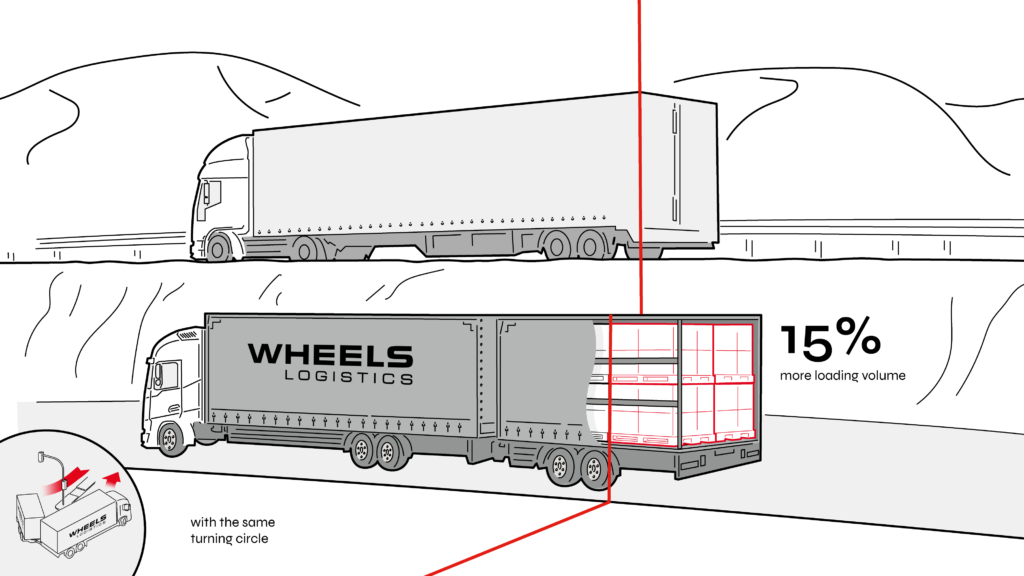

WHEELS Logistics enables more loading space with the Value Liner

At WHEELS Logistics, the responsible use of resources is a top priority. Our Value Liner shows what this means in practice: we have modified our articulated trucks so that they offer a significant loading space advantage. This protects the environment – and the wallet.

„In road freight transport, the available resources in Germany are often not used optimally,“ says Sven Patrias, Managing Director of WHEELS Logistics Germany. One example: Sven estimates that traditional articulated trucks currently account for around 80 percent of road transportation. However, with their standard dimensions of 13.60 meters, they have a clear disadvantage in terms of loading capacity.

The better alternative is articulated trucks consisting of a truck and trailer. Here, a maximum total length of 18.75 meters is permitted, and the loading area may measure a maximum of 15.60 meters. „We want to use as much space as possible and thus get the most out of it,“ emphasizes Sven.

Custom-made products make the difference

WHEELS Logistics relies on a sophisticated concept for loading space management: „We have divided up the net loading area of 15.60 meters in such a way that we can cover all standard pallet and pallet cage dimensions,“ says Sven. „This is an advantage over the conventional semi-trailer.“

In the articulated trucks that are generally used, the truck and trailer have the same size loading area. This poses a problem, as this layout is not ideal, especially for transporting various industrial load carriers: „With a symmetrical articulated train, there is always empty space. This is exactly what we avoid with our Value Liner,“ continues Sven.

Loading space advantage of 15 percent

The solution is: manual work. A body manufacturer modifies the truck and trailer exactly to the specifications of WHEELS Logistics. In the end, the loading area is divided asymmetrically to optimize the payload. This means, for example, that 26 pallets of cans can be transported, rather than just 22 pallets with German dimensions, as would be the case without modifications.

„With the Value Liner, we save on ramp contacts, we have less administrative work, fewer delivery bills and less idle time at the ramps,“ says Sven, listing the advantages of the asymmetric vehicles. Not to forget: The extra load reduces CO2 emissions and the resources used – from the driver to the fuel.